Design and manufacturing of our creations

Where are your decorations made?

All the decorations, wall clocks, wall ornaments, bookends and lamps are made in Warsaw, Poland, where I live. In fact, it's a purely European manufacturing process. I'm French and I design all the models, which are then cut on German, Swiss or Italian machines and painted with pigments made in Poland. The mechanisms of our clocks are made in Germany.

.The fact that I live where my creations are made allows me to have direct oversight of the manufacturing process and quality control.

Can you tell us about the creative process?

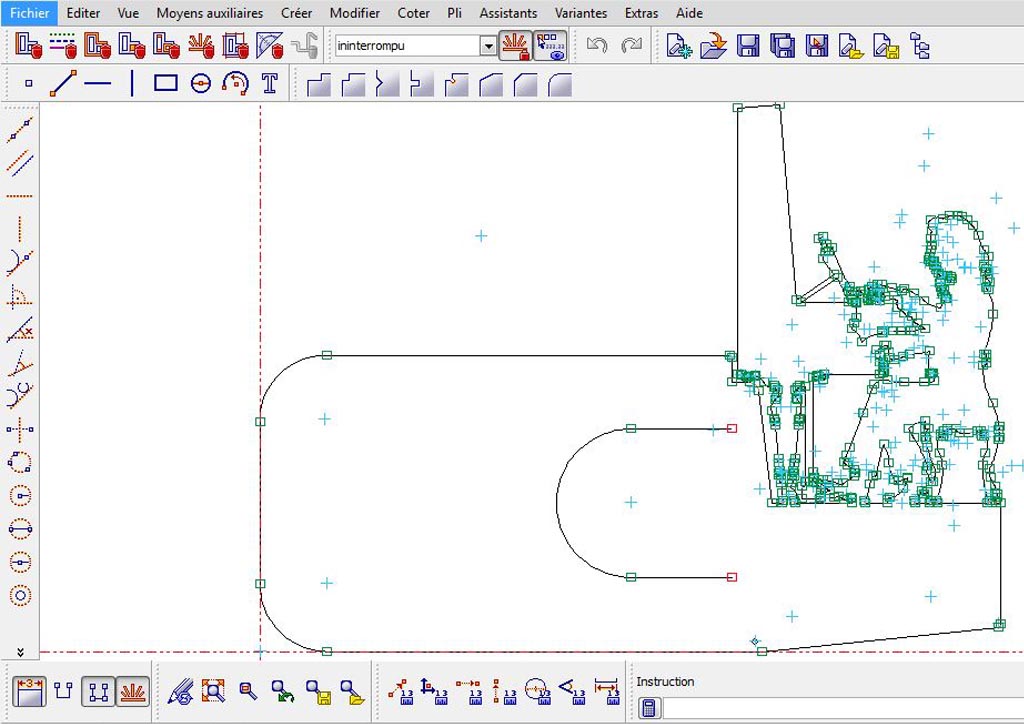

Initially, I create most models freehand, depending on the themes to be designed, while others are traced directly on the computer. The sketches obtained are then digitized and transferred to the screen to obtain finished vector files, which are the result of a pencil line transposed into a series of geometric shapes (arcs, segments, etc.). At this level, we obtain a fairly standard vector file which can be used for computer graphics, but which is not sufficient for laser cutting on metal. In fact, this process requires us to take into account certain technical constraints, such as the fineness of the shapes to be cut, cross-sections, optimization of the cutting itself when the laser head is moved, and adaptation of the vector file to a proprietary format (e.g. geo format for Trumpf machines). Finally, decorations are created in two stages: artistic and technical.

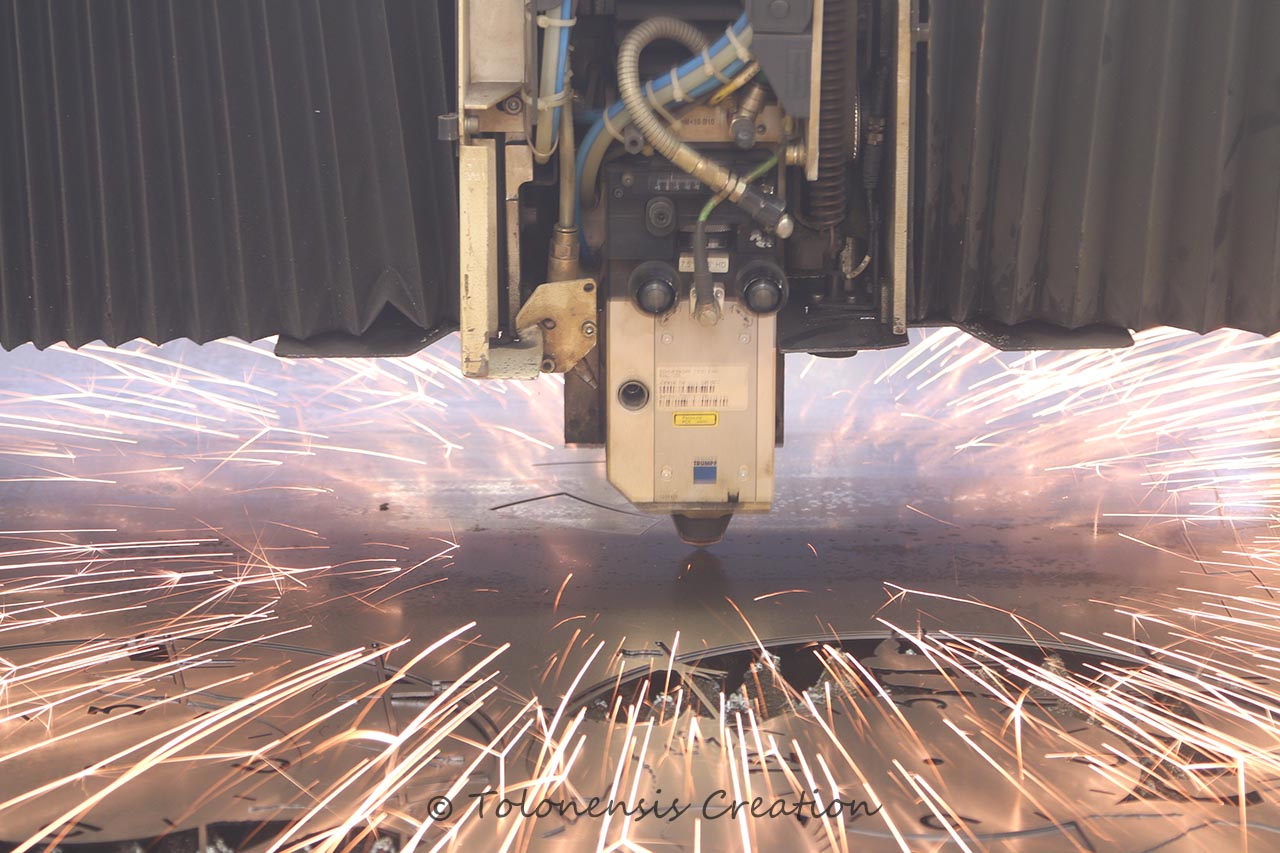

And what about manufacturing?

I use the services of few partners specializing in laser cutting. The machines used are large, high-tech, high-precision pieces of equipment, installed in industrial halls. Their purpose is to cut a wide variety of parts used in many fields of industry, including automotive and aeronautics. Depending on the type of material being cut - stainless steel, steel, aluminum, etc. - a gas is injected, either nitrogen or oxygen, during the cutting process. Our decorations are produced on DC01 quality steel plates, an industrial standard that defines cold rolling and guarantees rigorous flatness. Depending on the type of decoration required, thicknesses vary from 1.5 to 3 mm. Bookends and other decorative parts are bent on hydraulic presses by an operator.

Laser-cut of the clock Birdy

The bending process of bookends

The drawing of Chopin bookend on a CAD workstation

How do you go about coloring?

Before proceeding to this stage, the painter degreases and cleans the decorations. The painting treatment is carried out using the powder-coating technique. This consists in electrically polarizing the decorations so that the powder, which is diffused by a spray gun, covers all parts of the decoration uniformly, right down to the smallest nooks and crannies. The decorations are then placed in an oven heated to 280° for around twenty minutes. Painting is a delicate stage, as the painter must apply a thin layer of pigment to ensure that our decorations retain all their detail. The colors used are taken from the RAL color chart. Virtually all our decorations are painted in matte black RAL 9005. This technique does not allow several colors to be applied simultaneously to the same surface. However, we are able to offer customized decorations with 2 or 3 colors, each color being applied to a separate plate. The plates are then joined together, and the recessed parts, which have been judiciously arranged during the design stage, offer a final multi-color appearance.

Cleaning bookends before the painting process

Do you offer the possibility of personalizing your decorations?

In fact, we offer the possibility of personalizing some of our standard decorations. This can take the form of different sizes or colors. On our large-format decorations, we can offer lighting systems to provide a stunning visual effect when illuminated at certain times. To achieve this, we use lines of separate modules consisting of 3 LEDs. Power is supplied either by a standard electrical adapter or by a DC/AC converter box which can be integrated. Some of our large-format decorations can also be fitted with an integrated 55cm-wide digital clock.

But above all, personalization means offering custom-made creations to meet the specific needs of individuals, according to their interior design and decoration projects.

How are your creations marketed?

They are mainly offered via our online sales sites, but also on the platform Etsy and on marketplaces such as Allegro or Empik in Poland. A specific collection we created especially for the French public cultural institution Réunion des Musées Nationaux is offered to visitors to some of France's major museums, as well as on their sites de vente en ligne. We distribute our products mainly in Europe and across the Atlantic.

What sets you apart?

We make it a point of honor to offer quality products, produced in small batches or on demand, that stand out from the large-scale Asian productions so prevalent on the decoration market. Our creations are inspired by classic themes, which are always appreciated, or by themes such as our bookends. Some of our decorations, like the Little Planet series, remain unique because they are more complex to make.

Following the success of certain models, such as our Birdy clock, we have had to face up to a problem of illegal copies, and we warn our customers against this scourge. Our creations remain very affordable and our customers' feedback attests to the overall quality of our services.